ACE-1325 Two Heads CNC Router DSP Control

Model: ACE-1325ETR-2

Category: Multi heads CNC Router

Brand: ACETECH

Standard Price: 4400 USD

Price Range: 4400 - 14000 USD

Warranty: 2 years

Delivery Time: 10-15 working days

Supply Ability: 300 sets/month

Payment Terms: T/T 50% in advance and the balance paid before delivery

Product description:

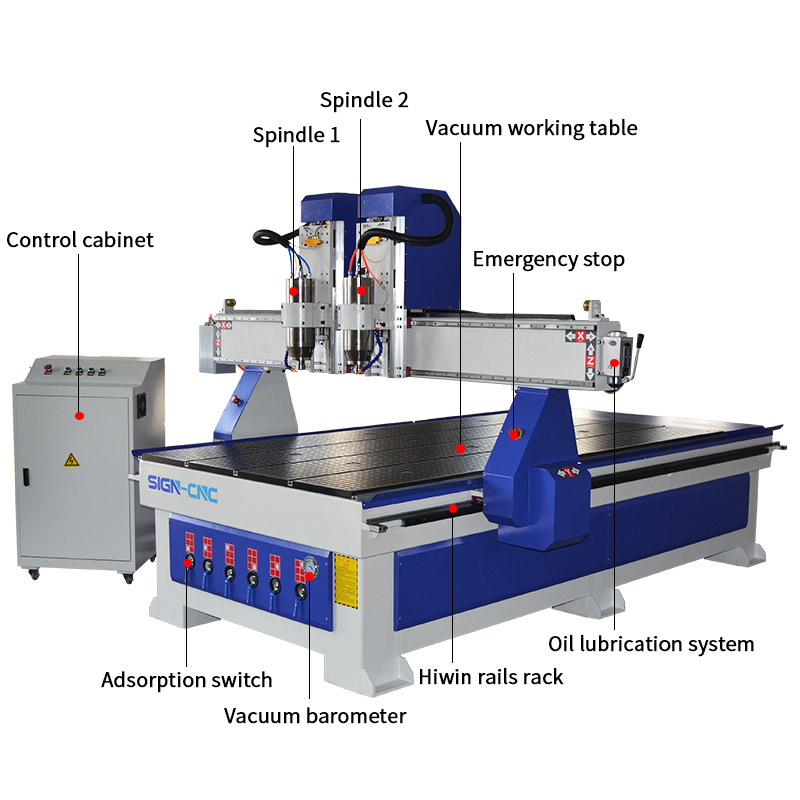

Machine with two heads and each head independent.

Two heads working at same time and for same work, double work efficiency

Vacuum table according your demand

Taiwan Hiwin square guide rails and Helical rack transmission

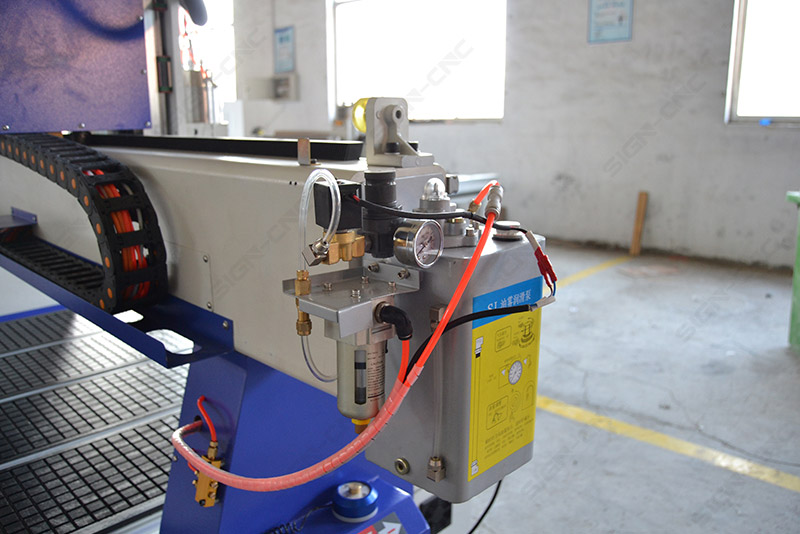

Oil lubrication system, inject oil for the machine rails, keeping machine move smoother

Tool sensor to adjust the distance from materials to cutter automatically.

Breakpoint memory, can continue to work after power off & breaking knife

Technical Parameters:

| Model | ACE-1325ETR-2 | ACE-1530ETR-2 | ACE-2030ETR-2 |

| X, Y Working size | 1300*2500mm | 1500*3000mm | 2000*3000mm |

| Z feed Height | 200mm | ||

| Table Surface | Vacuum with T-slot table | ||

| X, Y Structure | Rack and Pinion, Taiwan Linear Square Guide Rail | ||

| Z Structure | Taiwan Linear Square Guide Rail and Ball Screw | ||

| Max. Power Consumption | (Without spindle) 2.0Kw | ||

| Max. Rapid Travel Rate | 33000mm/min | ||

| Max. Working Speed | 25000mm/min | ||

| Spindle Power | 3.7kw water cooling spindle (air cooling type for option) | ||

| Vacuum pump | 5.5kw | ||

| Spindle Speed | 0-24000RPM | ||

| Drive Motors | Stepper motor and driver | ||

| Working Voltage: | AC220V or 380V /50/60Hz | ||

| Command Language | G code | ||

| Control System | DSP | ||

| Oil mist cooling system | Yes | ||

| Oil lubrication system | Yes | ||

| X,Y,Z repositioning Accuracy | ±0.01mm | ||

| X,Y Resolution | <0.01mm | ||

| Software | Artcam | ||

| Running Temperature | 0 degree - 45 degree | ||

| Relative Humidity | 30% - 75% | ||

| Optional Parts | Servo motorRotary systemPanasonic / Yaskawa Servo motors | ||

Contain:

| NO. | Mane | Features and use | Quantity |

| 1 | Frame of machine bed | Heavy duty large tube welding | 1 set |

| 2 | Gantry | Whole casting | 1 set |

| 3 | Spindle | Water cooling spindle | 2 pcs |

| 4 | Water pump | Cooling the spindle motor | 2 pcs |

| 5 | Inverter | To adjust the motor speed to achieve environmental protection and energy saving. | 2 pcs |

| 6 | Vacuum table with T-slot | Adsorb the material on the table for fix | 1 set |

| 7 | Vacuum pump | 5.5kw | 1 pc |

| 8 | Vacuum barometer | Indicating vacuum pressure value | 1 pc |

| 9 | Motor | Stepper | 6 sets |

| 10 | Driver | Leadshine | 6 sets |

| 11 | DSP | Control system | 1 set |

| 12 | Control cabinet | Computer cabinet and electrical component installation | 1 pcs |

| 13 | Guide rails | Hiwin square guide rails | 1 set |

| 14 | Rack gear | Helical rack and gear | 1 set |

| 15 | T-slot working table | Aluminum profiles | 1 set |

| 16 | Oil lubrication system | Lubrication the rails and rack gear | 1 pcs |

| 17 | Oil mist cooling system | For cooling the cutter tools when engraving metal | 1 pc |

| 18 | Emergency stop button | In case of unexpected situations, you can suspend urgently, more safer. | 3 pcs |

| 19 | Collets | Hold the bit on the spindle | 4 pcs |

| 20 | Fixture / Materials holder | Fixing material when engraving | 8 set |

| 21 | CD for Artcam software | Drawing engraving files | 1 set |

| 22 | Cutter | Used for engraving and cutting | 2 box |

| 23 | Connecting cables | Data Cable, Power Cable, etc. | 1 set |

| 24 | Wrench | Used for change the cutter or routine maintenance | 2 pcs |

| 25 | L-type screwdriver | Used for L-type screwdriver | 1 set |

| 26 | Water pump | Cooling the spindle motor | 2 set |

| 27 | Tool box | Loading tools and some gadgets | 1 pcs |

Pictures of machine: