A4-1325-L8 Linear ATC CNC Router Syntec control system

Model: A4-1325-L8

Category: Most Versatile CNC Router

Brand: ACETECH

Standard Price:

Price Range:

Warranty: 2 years

Delivery Time: 10-15 working days

Supply Ability: 300 sets/month

Payment Terms: T/T 50% in advance and the balance paid before delivery

Feature of the machine:

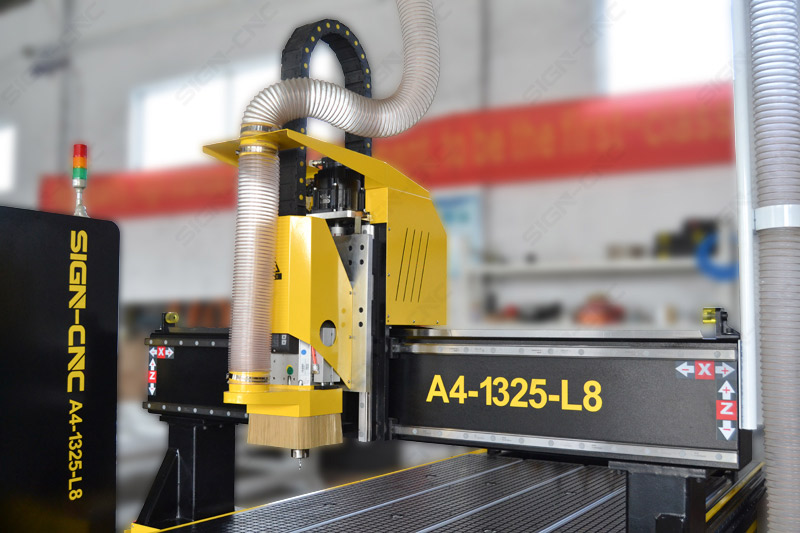

1. High-quality HQD 9.0 kw air-cooling spindles, ensures efficient operation.

2. Servo motor and driver, higher precision.

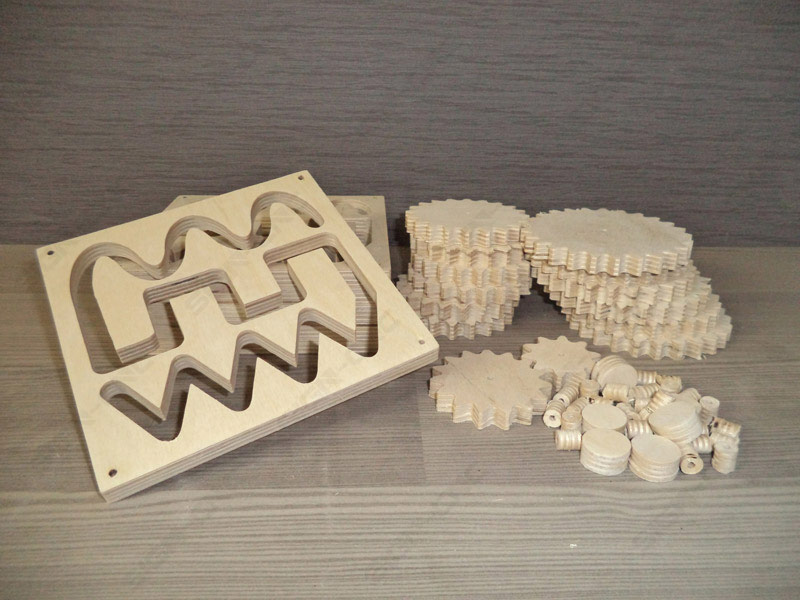

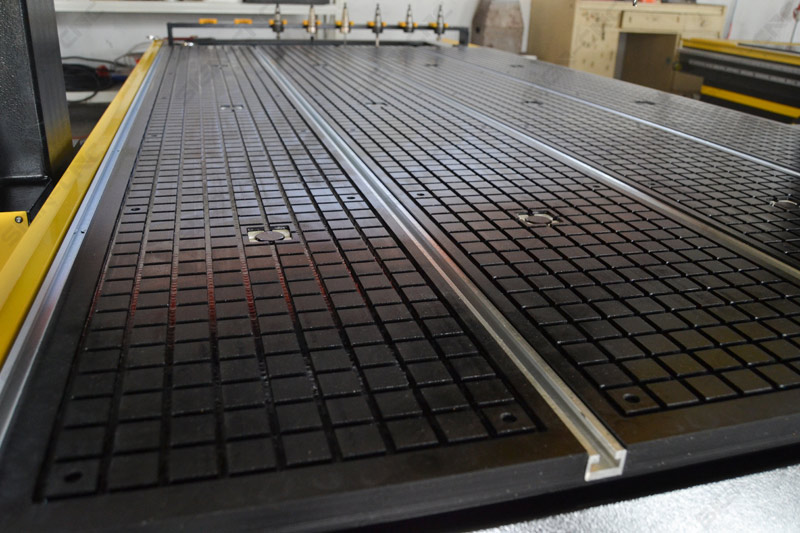

3. Vacuum table with T-slot (Clamps) table, more convenient for woodworking.

4. Heavy Reliable steel frame, six lag more stable.

5. Different working size 1300 * 2500mm / 1500*3000mm/2000*3000mm dependent on your choose and more practical for woodworking.

6. The oil lubrication system ensures the stability of mechanical parts.

7. 8-12 Tool Magazine, Tool changer automatically, many times increases productivity.

8. SYNTEC control system is more convenient to operate the machine for processing 2D, 3D engraving.

9. Hiwin 25 square guide rails and rack transmission

10. Breakpoint memory, can continue to work after power off & breaking knife

11. Positioning pneumatic cylinder design to fix the plate faster and more accurately, improving work efficiency

12. Machine with Oil mist cooling system for metal materials engraving and cutting

Technical Parameters:

| Model | A4-1325-L8 | |

| X, Y Working size | 1300*2500mm | |

| Z feed Height | 300mm | |

| Table Surface | Vacuum working table with 5.5kw/7.5kw vacuum pump | |

| X, Y Structure | Rack and Pinion Drive, Hiwin 25 Linear Square Guide Rail | |

| Z Structure | Hiwin 25 Linear Square Guide Rail and Ball Screw | |

| Spindle Power | 9.0kw HQD spindle | |

| Inverter | 11KW | |

| Linear tools magazine | 8 PCS | |

| Max. Rapid Travel Rate | 33000mm/min | |

| Max. Working Speed | 25000mm/min | |

| Tool sensor | With | |

| Dust collector | 3kw | |

| Spindle Speed | 0-24000RPM | |

| Drive Motors | Servo motor and driver | |

| Working Voltage: | AC 380V | |

| Command Code | G code | |

| Control System | Syntec 60WE | |

| Tool Magazine | 8-12 PCS | |

| X,Y,Z repositioning Accuracy | ±0.01mm | |

| X,Y Resolution | <0.01mm | |

| Software | Artcam | |

| Lubrication system | Automatically | |

| Sensor for positioning the cutter | Yes | |

| Running Temperature | 0 degree – 45 degree | |

| Relative Humidity | 30% - 75% | |

| Warranty | Two year | |

Contain

NO. | Mane | Features and use | Quantity |

1 | Frame of machine bed | Heavy duty large tube welding | 1 set |

2 | Gantry | Whole casting | 1 set |

3 | Spindle | Water cooling or air cooling | 1 pc |

4 | Water pump | Used for cooling the spindle motor | 1 pc |

5 | Inverter | 4kw | 1 pcs |

6 | Motor | Stepper | 4 sets |

7 | Driver | Leadshine | 4 sets |

8 | NCstudio | Control system | 1 set |

9 | Control cabinet | Computer cabinet and electrical component installation | 1 pc |

10 | Guide rails | Hiwin square guide rails | 1 set |

11 | Rack gear | Helical rack and gear | 1 set |

12 | Vacuum working table with T-slot | Adsorb the material on the table | 1 set |

13 | Vacuum pump | 5.5kw | 1 set |

14 | Vacuum barometer | Indicating vacuum pressure value | 1 pc |

15 | Oil lubrication system | Lubrication the rails and rack gear | 1 pcs |

16 | Emergency stop | One on control box and two on Y axis motor | 3 pc |

17 | Tool sensor | Adjust the distance from the tool to the materials | 1 pc |

18 | Collets | Hold the bit on the spindle | 4 pcs |

19 | Materials holder | Fixing material when engraving | 8 set |

20 | CD for Artcam software | Drawing engraving files | 1 set |

21 | Cutter | Used for engraving and cutting | 2 box |

22 | Connecting cables | Data Cable, Power Cable, etc. | 1 set |

23 | Wrench | Used for change the cutter or routine maintenance | 2 pcs |

24 | L-type screwdriver | Screwing tools | 1 set |

25 | Tool box | Loading tools and some gadgets | 1 pcs |

Pictures of machine parts:

Option:

Rotary for cylindrical materials engraving

Servo motor and driver

Packing & Delivery

All the machine parts have been packaging, and whole of the machine with waterproofing membrane. And then have been package use standard wood case (The fumigation-free ), on the case top and bottom have steel tube for support. Let it more stronger to avoid damage during the transport and for long distance transportation.