A3-1325-4 ATC CNC router pneumatic multi heads/ spindles

Model: A3-1325-4

Category: ATC CNC Router

Brand: ACETECH

Standard Price:

Price Range:

Warranty:

Delivery Time:

Supply Ability: 30 SET/ MONTH

Payment Terms: T/T 50% in advance and the balance paid before shipping

Feature of the machine:

1. Two air-cooled spindles, These spindles can change automatically during working according your file.

2. Hiwin/TBI square guide rails and rack transmission.

3. T-slot (Clamps) table, more convenient for woodworking.

5. Two spindles change automatically, many times increases productivity.

6. Heavy Reliable steel frame, six lag more stable.

7. The lubrication system ensures the stability of mechanical parts.

8. DSP control system, easy and convenience operate

9. Machine with dust collector let the workshop more clean during working

10. Breakpoint memory, can continue to work after power off & breaking tool cutter

Application:

Wood furniture Industry, Furniture decoration, music instrument, wooden arts and crafts, large scale board engraving, solid wood furniture, solid wooden mural, composite door, free-paint door, cabinet doors, advertising industry, Die industry, Relief sculpture, toy production, bedside cupboard, screen sculpture etc.

Materials:

Woods, acrylics, artificial stones, artificial marble, bamboos, organic boards, double-color board, PVC board, aluminum, brass and other materials.

Technical Parameters:

| Model | A3-1325-4 | ||

| Working area | 1300*2500mm | ||

| Z feeding | 300mm | ||

| Type of table cover | T-slot | ||

| X Y axis transmission | Hiwin square guide rails + rack | ||

| Z axis transmission | Ball screw and square guide rails | ||

| Max. Rapid Travel Rate | 33000mm/min | ||

| Max. Working Speed | 25000mm/min | ||

| Command Code | G code * .u00 * .mmg * .plt | ||

| Operating voltage | AC 380V/50Hz | ||

| Spindle power | HQD 3.5kw / 4.5kw / 6.0kw | ||

| Spindles | 2/3/4 spindles | ||

| Type of cooling | Air cooling | ||

| Spindle Speeds | 0-24000rpm/min | ||

| Drive motor type | Stepper motor and driver (servo motor is option) | ||

| operating system | DSP A15 | ||

| Dust Collector | Double bags | ||

| Lubrication system | Yes | ||

| Sensor for positioning the cutter | Yes | ||

| Supported software | Artcam software, Type3 software | ||

| Operating conditions | Humidity: 30% -75%, temperature: 15 - 45 degree | ||

| Warranty | Two year | ||

Contain:

| NO. | Name | Features and use | Quantity |

| 1 | Frame of machine bed | Large steel tube welding | 1 set |

| 2 | Gantry | Heavy duty | 1 set |

| 3 | Spindle | Air cooling spindle | 2 pc |

| 4 | Inverter | BEST | 1 pc |

| 5 | Motor | Stepper / Servo | 4 sets |

| 6 | Driver | Stepper / Servo | 4 sets |

| 7 | DSP handle | DSP A15 | 1 set |

| 8 | Barometer | Two show the barometric pressure when vacuum pump working for fix the materials | 1 pc |

| 9 | Control cabinet | Computer cabinet and electrical component installation | 1 pc |

| 10 | Barometer | Indicating vacuum pressure value | 1 pc |

| 11 | Guide rails | Hiwin brand square guide rails | 1 set |

| 12 | Rack gear | X Y use helical rack and gear | 1 set |

| 13 | Ball screw | Z axis transmission | 1 pc |

| 14 | Oil lubrication system | Lubrication the rails and rack gear | 1 pc |

| 15 | Dust collector | Collect wood chips from engraving to clean the air | 1 pc |

| 16 | Tool sensor | Adjust the distance from the tool to the materials | 1 pc |

| 17 | Working table | T-slot | 1 set |

| 18 | Vacuum pump | Suction the air between the material and the table to be a vacuum to fix the material. | 1 pc |

| 19 | Emergency stop | One on control box and two one Y axis motor | 3 pc |

| 20 | Collets | Hold the bit on the spindle | 8 pcs |

| 21 | Materials holder | Fixing material when engraving | 8 set |

| 22 | CD for Artcam software | Drawing engraving files | 1 set |

| 23 | Cutter | Used for engraving and cutting | 2 box |

| 24 | Connecting cables | Data Cable, Power Cable, etc. | 1 set |

| 25 | Wrench | Used for change the cutter or routine maintenance | 2 pcs |

| 26 | L-type screwdriver | Used for L-type screwdriver | 1 set |

| 27 | Tool box | Loading tools and some gadgets | 1 pc |

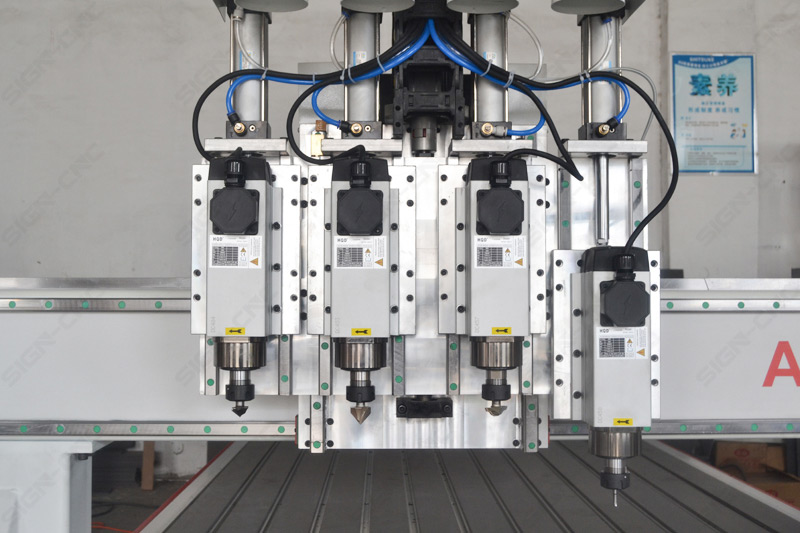

Details pictures: