ACE-2141 Pneumatic ATC cnc router engraving machine

Model: ACE-2141ATC-M2

Category: ATC CNC Router

Brand: ACETECH

Standard Price: 7350 USD

Price Range: 7350-19000 USD

Warranty: 2 years

Delivery Time: 10-15 working days

Supply Ability: 300 sets/month

Payment Terms: T/T 50% in advance and the balance paid before delivery

Feature of the machine:

Pneumatic is similar as ATC cnc router, spindle change instead of tool change.

1. Two air-cooled spindles, These spindles can change automatically during working according your file.

2. Hiwin/TBI square guide rails and rack transmission.

3. Vacuum table with T-slot (Clamps) table, more convenient for woodworking.

4. Eight partitions for vacuum table and with two barometer connect two vacuum pump

5. Two spindles change automatically, many times increases productivity.

6. Big working area to meet required for processing of large format materials

7. Heavy Reliable steel frame, six lag more stable.

8. The lubrication system ensures the stability of mechanical parts.

9. Original NCstudio control system

10. Machine with dust collector let the workshop more clean during working

11. Breakpoint memory, can continue to work after power off & breaking tools cutter

Application:

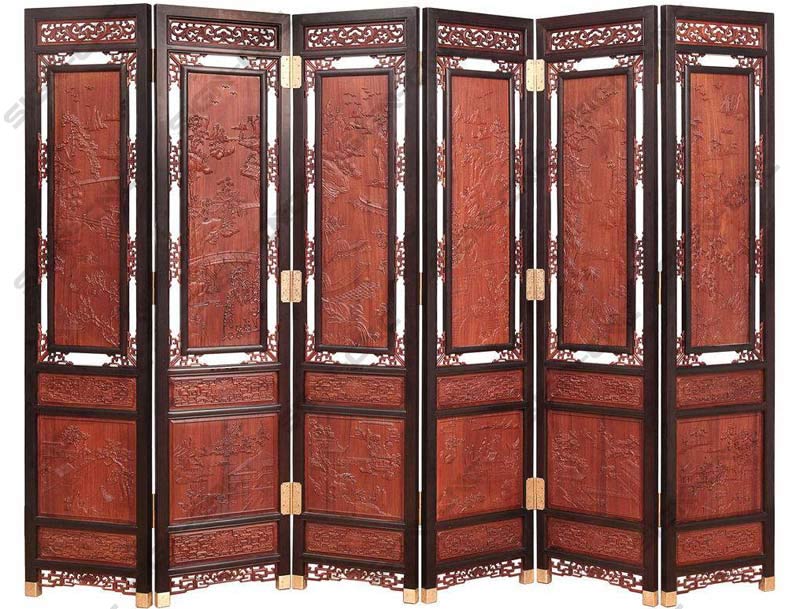

Wood furniture Industry, Furniture decoration, music instrument, wooden arts and crafts, large scale board engraving, solid wood furniture, solid wooden mural, composite door, free-paint door, cabinet doors, advertising industry, Die industry, Relief sculpture, toy production, bedside cupboard, screen sculpture etc.

Materials:

Woods, acrylics, artificial stones, artificial marble, bamboos, organic boards, double-color board, PVC board, aluminum, brass and other materials.

Technical Parameters:

| Model | ACE-2141ATC-M2 |

| Working area | 2100*4100mm |

| Z feeding | 200mm |

| Type of table cover | Vacuum table with T-slot |

| Vacuum pump | 5.5kW/7.5kw air cooling |

| X Y axis transmission | Hiwin square guide rails + rack |

| Z axis transmission | Ball screw and square guide rails |

| Max. Rapid Travel Rate | 33000mm/min |

| Max. Working Speed | 25000mm/min |

| Command Code | G code * .u00 * .mmg * .plt |

| Operating voltage | AC 380V/50Hz |

| Spindle power | HQD 3.5kw / 4.5kw / 6.0kw |

| Spindles | 2 spindles dependent on your demand |

| Type of cooling | Air cooling |

| Spindle Speeds | 0-24000rpm/min |

| Drive motor type | Stepper motor and driver (servo motor is option) |

| operating system | DSP |

| Dust Collector | Double bags |

| Lubrication system | Yes |

| Sensor for positioning the cutter | Yes |

| Supported software | Artcam software, Type3 software |

| Operating conditions | Humidity: 30% -75%, temperature: 15 - 45 degree |

| Warranty | Two year |

Contain:

| NO. | Name | Features and use | Quantity |

| 1 | Frame of machine bed | Large steel tube welding | 1 set |

| 2 | Gantry | Heavy duty | 1 set |

| 3 | Spindle | Air cooling spindle | 2 pc |

| 4 | Inverter | Fuling | 1 pc |

| 5 | Motor | Stepper / Servo | 4 sets |

| 6 | Driver | Stepper / Servo | 4 sets |

| 7 | DSP | Machine control system like the human brain | 1 set |

| 8 | Emergency stop | One on control box and two on Y axis motor | 3 pc |

| 9 | Control cabinet | Computer cabinet and electrical component installation | 1 pc |

| 10 | Vacuum pump | Suction the air between the material and the table to be a vacuum to fix the material. | 2 pc |

| 11 | Barometer | Indicating vacuum pressure value | 2 pc |

| 12 | Guide rails | Hiwin brand square guide rails | 1 set |

| 13 | Rack gear | X Y use helical rack and gear | 1 set |

| 14 | Ball screw | Z axis transmission | 1 pc |

| 15 | Oil lubrication system | Lubrication the rails and rack gear | 1 pc |

| 16 | Dust collector | Collect wood chips from engraving to clean the air | 1 pc |

| 17 | Tool sensor | Adjust the distance from the tool to the materials | 1 pc |

| 18 | Working table | Vacuum table with T-slot | 1 set |

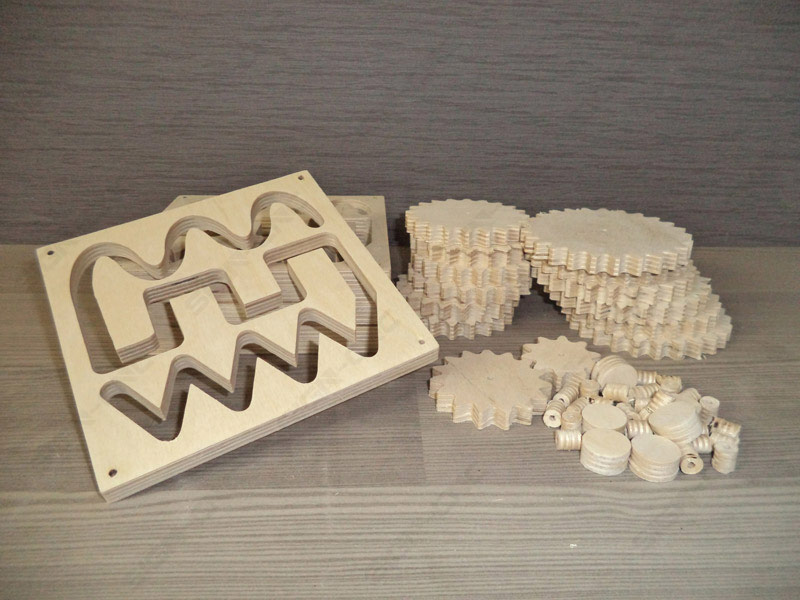

| 19 | Collets | Hold the bit on the spindle | 8 pcs |

| 20 | Materials holder | Fixing material when engraving | 8 set |

| 21 | CD for Artcam software | Drawing engraving files | 1 set |

| 22 | Cutter | Used for engraving and cutting | 2 box |

| 23 | Connecting cables | Data Cable, Power Cable, etc. | 1 set |

| 24 | Wrench | Used for change the cutter or routine maintenance | 2 pcs |

| 25 | L-type screwdriver | Used for L-type screwdriver | 1 set |

| 26 | Tool box | Loading tools and some gadgets | 1 pc |

This series of machines can be equipped with 2, 3 or 4 spindles as required. The advantage of the device lies in the freedom to switch between different processing modes in one file. For example, a spindle engraving, a spindle drilling, and a spindle cutting. If the budget is not enough, you can consider the ordinary double head, or our best-selling woodworking machine, the price starts from USD 3000, if you want to process a single file, more than 4 times of tool change (different processing mode), we have ATC to choose from. For details, please contact us.

We are a professional manufacturer with our own R&D team and factory. If this is not suitable for you, please tell us your specific required and budget, we will definitely provide the most suitable solution.

Details pictures:

Option part:

1. Rotary.

We can make it according your needs add different diameter rotary. And we also can make it with 4 axis linkage system. And the rotary can be removed when you carving the big planar materials.

2. Servo motor

Japanese Yaskawa or Panasonic servo motor as your choose.