A8-2140-L8 ATC CNC Router Machine 4Axis Swing head for 3D Model

Model: A8-2140-L8

Category: ATC CNC Router

Brand: ACETECH

Standard Price:

Price Range:

Warranty: 2 years

Delivery Time: 10-15 working days

Supply Ability: 300 sets/month

Payment Terms: T/T 50% in advance and the balance paid before delivery

Feature of the machine:

1. High-quality HSD 9.0 kw air-cooling spindles, ensures efficient operation.

2. YASKAWA Servo motor and driver, higher precision.

3. Vacuum table with T-slot (Clamps) table, more convenient for woodworking.

4. Heavy Reliable steel frame, six lag more stable.

5. Different working size 1300 * 2500mm /1500*2500mm/2000*3000mm dependent on your choose and more practical for woodworking.

6. Lubrication system ensures the stability of mechanical parts.

7. 8-12 Tool Magazine, Tool changer automatically, many times increases productivity.

8. Taiwan's SYNTEC control system is more convenient to operate the machine for processing 2D, 3D engraving.

9. Hiwin 25 square guide rails and rack transmission

10. Breakpoint memory, can continue to work after power off & breaking knife

11. Positioning pneumatic cylinder design to fix the plate faster and more accurately, improving work efficiency

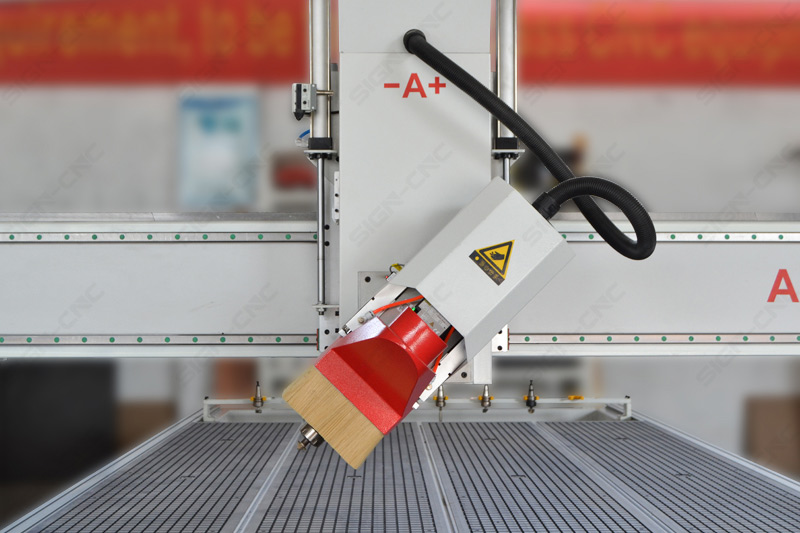

12.180 degree swing head 4axis system .

Application:

Wood ;furniture ;Industry, Furniture ;decoration, ;music ;instrument, wooden arts and crafts, large scale board engraving, solid wood furniture, solid wooden mural, composite door, free-paint door, cabinet doors, advertising industry, Die industry, ;Relief sculpture, toy production, bedside cupboard, screen ;sculpture etc.

Materials:

Woods, acrylics, artificial stones, artificial marble, bamboos, organic boards, double-color board, PVC board, aluminum, brass and other materials.

Technical Parameters:

| Model | A8-2140-L8 | |

| X, Y Working size | 2100*4000mm | |

| Z feed Height | 300/400mm | |

| Table Surface | Vacuum working table with 5.5kw/7.5kw vacuum pump | |

| X, Y Structure | Rack and Pinion Drive, Hiwin 25 Linear Square Guide Rail | |

| Z Structure | Hiwin 25 Linear Square Guide Rail and Ball Screw | |

| Spindle Power | 9.0kw HSD spindle | |

| Inverter | 11KW | |

| Linear tools magazine | 8-12 PCS | |

| Max. Rapid Travel Rate | 33000mm/min | |

| Max. Working Speed | 25000mm/min | |

| Tool sensor | With | |

| Dust collector | 3kw | |

| Spindle Speed | 0-24000RPM | |

| Drive Motors | YASKAWA Servo motor and driver | |

| Working Voltage: | AC 380V | |

| Command Code | G code | |

| Control System | Syntec 60WE | |

| Tool Magazine | 8-12 PCS | |

| X,Y,Z repositioning Accuracy | ±0.01mm | |

| X,Y Resolution | <0.01mm | |

| Software | Artcam | |

| Lubrication system | Automatically | |

| Sensor for positioning the cutter | Yes | |

| Running Temperature | 0 degree - 45 degree | |

| Relative Humidity | 30% - 75% | |

| Warranty | Two year | |

Contain:

| NO. | Name | Features and use | Quantity |

| 1 | Frame of machine bed | Large steel tube welding | 1 set |

| 2 | Gantry | Heavy duty | 1 set |

| 3 | Spindle | 9kw HSD air cooling spindle | 1 pc |

| 4 | Inverter | 11kw Fuling | 1 pc |

| 5 | Motor | Panasonic servo motor | 4 sets |

| 6 | Driver | Panasonic servo driver | 4 sets |

| 7 | Syntec control card | 6MA | 1 set |

| 8 | Hand wheel | Operate for simple work | 1 pc |

| 9 | Control cabinet | Computer cabinet and electrical component installation | 1 pc |

| 10 | Rotary | Diameter is 200mm, for cylinder materials engraving | 1 pc |

| 11 | Guide rails | Hiwin 25 square guide rails | 1 set |

| 12 | Rack gear | Helical rack and gear | 1 set |

| 13 | Working table | Vacuum table with T-slot | 1 set |

| 14 | Vacuum pump | Suction the air between the material and the table to be a vacuum to fix the material. | 1 pc |

| 15 | Positioning pneumatic cylinder | To fix the plate faster and more accurately, improving work efficiency | 1 pc |

| 16 | Auto oil lubrication system | Lubrication the rails and rack gear | 1 pc |

| 17 | Dust collector | 3kw double bags | 1 pc |

| 18 | Tool sensor | Adjust the distance from the tool to the materials | 1 pc |

| 19 | Tool Magazine | Place of put the cutter with 8 position | 1 set |

| 20 | Collets | Hold the bit on the spindle | 8 pcs |

| 21 | Materials holder | Fixing material when engraving | 8 set |

| 22 | CD for Artcam software | Drawing engraving files | 1 set |

| 23 | Cutter | Used for engraving and cutting | 2 box |

| 24 | Connecting cables | Data Cable, Power Cable, etc. | 1 set |

| 25 | Wrench | Used for change the cutter or routine maintenance | 2 pcs |

| 26 | L-type screwdriver | Used for L-type screwdriver | 1 set |

| 27 | Tool box | Loading tools and some gadgets | 1 pc |

Pictures of machine parts:

Option part:

1. Rotary

We can make it according your needs add different diameter rotary. And we also can make it with 4 axis linkage system. And the rotary can be removed when you carving the big planar materials.

2. Automatic ;loading and unloading system

Loading and unloading automatically, will save manpower and time, reduce the produce costs, and also make the produce more easy and faster.

Package:

Whole machine have been package by plywood, and all the parts are including and fixed. Machine is wrapped with a waterproof bag and a stretch film to prevent the machine from rusting during transportation.