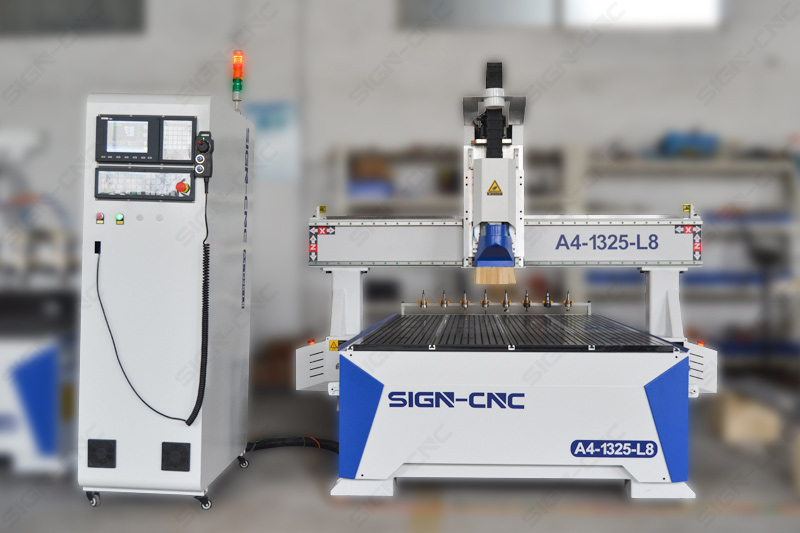

A4-1325-L8 ATC CNC router machine woodworking CNC router

Model: A4-1325-L8

Category: ATC CNC Router

Brand: ACETECH

Standard Price:

Price Range:

Warranty: 2 year

Delivery Time: 15 working days

Supply Ability: 300 set/month

Payment Terms: T/T 50% in advance and the balance paid before delivery

1. Feature of the machine:

Servo motor and driver, higher precision.

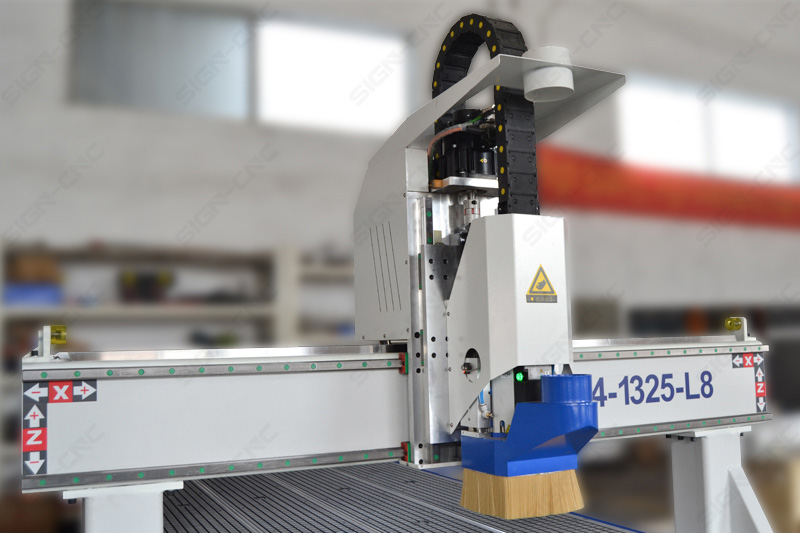

Tool setting gauge to set Tool position easily and correctly

Powerful 9.0 kw air-cooling spindles, one-button quick manual tool change.

Imported Hiwin square guide rails, rack and pinion transmission, high precision and strength

Adopt the whole plate welding structure, the machine heat treatment after one-time finishing forming.

The machine adopts unique rack dual drive structure, which improves the stability and tensile strength of the machine.

High flexible cable materials ensures that the machine is not easy to be broken in long-term repeated operation.

Vacuum table with T-slot (Clamps) table and 7.5kw vacuum pump, more convenient for woodworking.

Automatic lubrication system ensures the stability of mechanical parts.

Breakpoint memory, can continue to work after power off & breaking knife

2. Application:

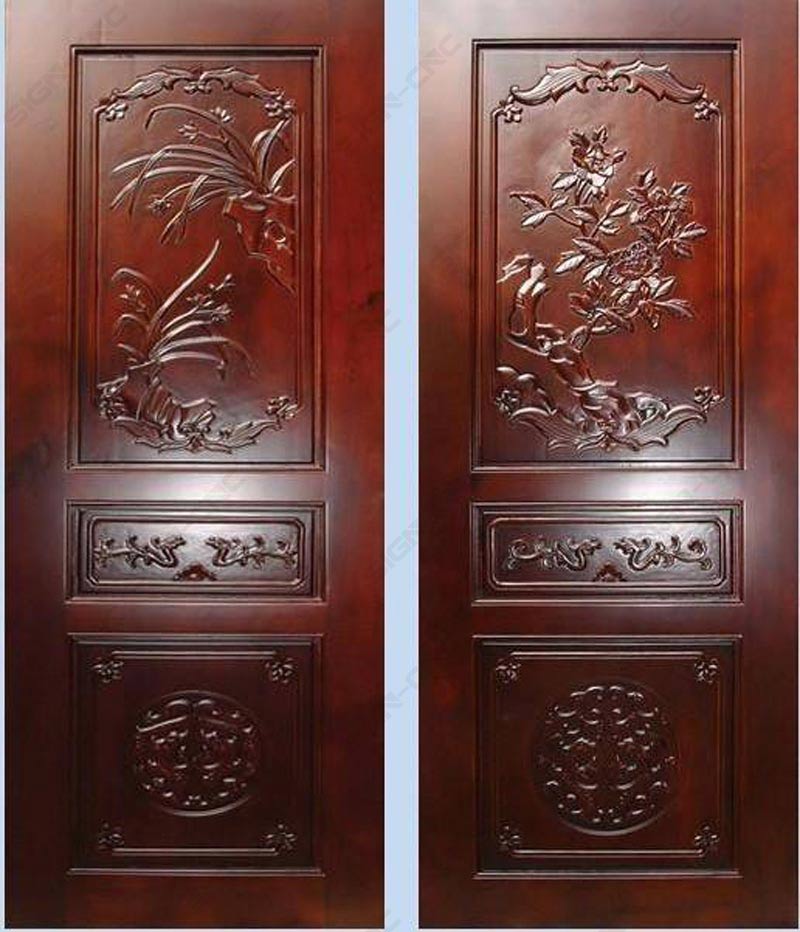

Wood furniture Industry, Furniture decoration, music instrument, wooden arts and crafts, large scale board engraving, solid wood furniture, solid wooden mural, composite door, free-paint door, cabinet doors, advertising industry, Die industry, Relief sculpture, toy production, bedside cupboard, screen sculpture etc.

3. Materials:

Woods, acrylics, artificial stones, artificial marble, bamboos, organic boards, double-color board, PVC board, aluminum, brass and other materials.

4. Technical Parameters:

| Model | A4-1325-L8 |

| X, Y Working size | 1300*2500mm |

| Z feed Height | 300mm |

| Table Surface | Vacuum working table with 7.5kw vacuum pump |

| X, Y Structure | Rack and Pinion Drive, Hiwin 25 Linear Square Guide Rail |

| Z Structure | Hiwin 25 Linear Square Guide Rail and Ball Screw |

| Spindle Power | 9.0kw HQD spindle |

| Inverter | 11KW |

| Max. Rapid Travel Rate | 33000mm/min |

| Max. Working Speed | 25000mm/min |

| Tool sensor | With |

| Dust collector | 3kw |

| Spindle Speed | 0-24000RPM |

| Drive Motors | Servo motor and driver |

| Working Voltage: | 380V |

| Command Code | G code |

| Control System | SYNTEC 60WE |

| X,Y,Z repositioning Accuracy | ±0.01mm |

| X,Y Resolution | <0.01mm |

| Software | Artcam |

| Lubrication system | Automatically |

| Sensor for positioning the cutter | Yes |

| Running Temperature | 0 degree - 45 degree |

| Relative Humidity | 30% - 75% |

| Warranty | Two year |

5. Pictures of machine parts

6. Option part:

Rotary

We can make it according your needs add different diameter rotary. And we also can make it with 4 axis linkage system. And the rotary can be removed when you carving the big planar materials.

Automatic loading and unloading system

Loading and unloading automatically, will save manpower and time, reduce the produce costs, and also make the produce more easy and faster.